AND

AND

| Packaging Product Assembly |

From the simplest of needs

to specifically engineered products, Glue Dots International and John Mulhern

Company are dedicated to providing the right product for every application.

These are some frequently

asked questions about Glue DotsŪ. Contact our R&D department with your

additional questions at info@jmulhern.com.

Q: Why should I use

Glue DotsŪ instead of other adhesives?

A: Glue Dots are faster and safer that hot glue guns, cleaner than liquid

adhesives and leave no sticky residue like double sided tapes. Eliminate hot

glue burns, fumes and set-up times with Glue Dots!

Q: Are Glue DotsŪ

safe to use?

A: Yes. Glue Dots are non-toxic, odorless, FDA-approved for indirect food

contact and conform to ASTM D-4236. Since glue guns are not necessary, the

chance of incurring serious burns from hot glue is eliminated.

Q: How can Glue DotsŪ

be more cost-effective when they're applied manually?

A: Glue Dots can be applied quickly and cleanly (reducing rejects from the

QC line), no set up time is required and no drying time is necessary. All of

these factors equate to better productivity and cost efficiencies.

Q: Can Glue DotsŪ be

used in an assembly line?

A: Incorporating Glue Dot Applicators into your assembly

process can increase your efficiencies.

Q: What materials do

Glue DotsŪ adhere to?

A: Glue Dots adhere to a wide variety of materials. Some examples include

paper, plastic, foil, glass, aluminum, cinderblock, Styrofoam, wood, and Teflon.

(If the substrates you're working with are questionable, contact John Mulhern

Company at info@jmulhern.com for a

recommendation.)

Q: How can I be assured

of the best bond possible?

A: Some substances may interfere with the bonding quality of Glue DotsŪ

such as moisture, oils, dust, hand lotions, and silicone-coated products. Always

make sure that surfaces are clean and dry in order for Glue Dots to adhere

properly.

Q: Why use a 3/4"

diameter product instead of 1/2" ?

A: Your choice will depend on the size/surface area of the materials you are

adhering. When using pressure-sensitive adhesives like Glue DotsŪ, there is a

direct correlation between the amount of surface contact and the overall

strength of the bond. 1/2" diameter Glue Dots (as well as several Glue

Shapes) are designed for maximum surface area contact.

Q: Do you manufacture

"fugitive" glue products?

A: The term "fugitive" commonly refers to removable adhesives.

Many of our products meet that definition.

Q: What is the

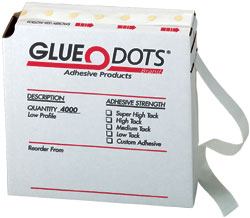

difference between "tack" and "profile"?

A: "Tack" refers to the

aggressiveness of the adhesive. Low tack Glue DotsŪ, for instance, are

removable whereas Super High tack Glue Dots would be considered permanent on

most surfaces.

"Profile" refers to the thickness of the Glue Dot. Low profile Glue Dots are very flat compared to High profile Glue Dots which are approximately 1/8" thick. Medium and High profile products are usually best suited for round, concave or irregularly shaped objects.

Q: Does it matter what

tack level I use?

A: Yes. As the end-user, you are the best judge of the bond strength

required for your application. Your Glue Dots Distributor can assist you in

determining the best product for your needs by supplying you with a variety of

samples to test.

Q: When should I

consider a custom pattern?

A: In those cases where unusual shapes or materials are used, or the bond is

under a great deal of stress, a custom pattern may be necessary. Based on your

application, your John Mulhern Company can advise you on the best product for

your needs.

Q: What is the shelf

life of Glue DotsŪ?

A: While Glue Dots will not degrade over time, contaminants such as moisture

and dust can interfere with the bonding qualities. We recommend you replace the

product after 18 months and always store in a clean, dry place.

Q: What are the hottest

and coldest temperatures Glue DotsŪ can withstand?

A: This will depend on the amount of stress the bond is under. In some

cases, our R&D department may develop a custom adhesive especially for your

application.